wooden bridge competition

January 2025

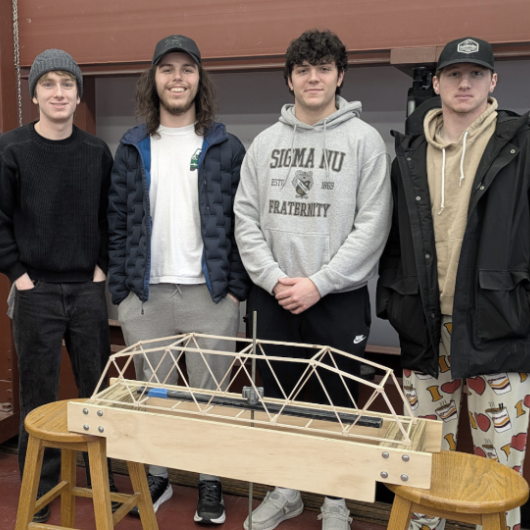

For the final project of Mechanics of Materials, me and three of my classmates were tasked with designing and constructing a bridge out of balsa wood. It would be evaluated based on strength to weight ratio.

Thanks to our unique design approach, our bridge was able to support three hundred times its weight.

analysis & design

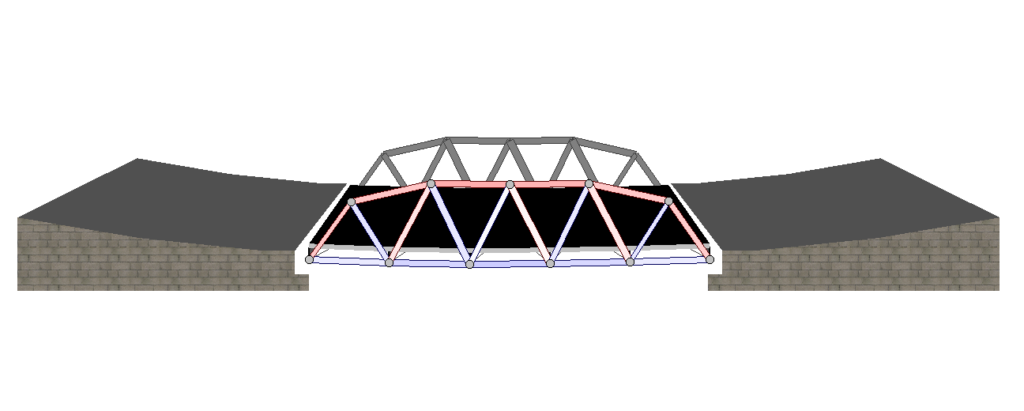

This project is meant to be an introduction to tension & compression member design. As such, the structural analysis software we were given was West Point Bridge Designer, a program that can calculate axial force in each member of a simple steel bridge truss.

Because our main design criteria was strength to weight ratio, we made the decision to consider the members’ axial stresses only in relation to each other. We theorized that, by choosing our cross-sectional areas correctly, we could normalize the stress in each member, such that every member would fail at once. This approach helped us greatly minimize excess material.

construction

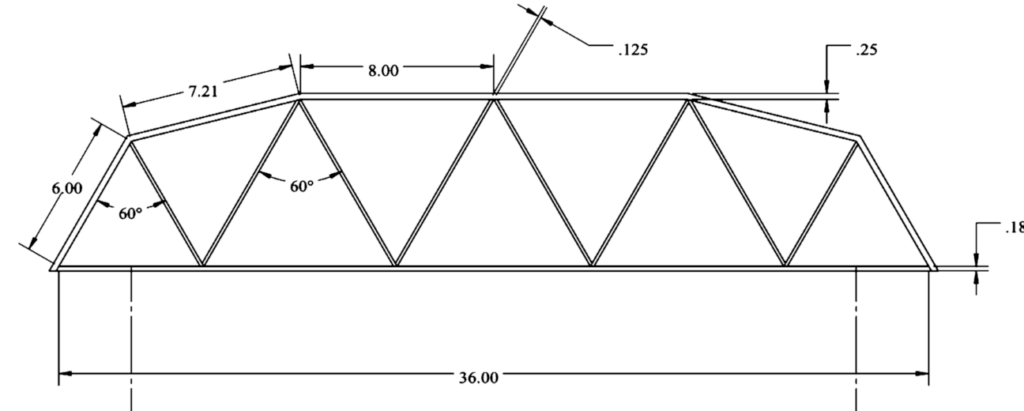

After we’d settled on the shape of our truss and the cross-sectional area of each member, I accepted the task of creating a precise CAD drawing of our truss.

The details of our connections were laid out such that almost every member was an integer length. The tools that we had could only cut angles at 30°, 45°, 60°, and 90°, so joints were all planned with that in mind. In addition, I printed scale diagrams of each member on paper for ease of fabrication and auditing.

My efforts made our construction process fast and precise, saving my team significant time and effort over the duration of the project.